by Brittany Martin, IPC/WHMA Marketing Coordinator

WHMA's Annual Global Leadership Summit proved to be a resounding success, drawing in nearly 200 professionals from the wire harness and electronics industries to engage in workshops, networking sessions, and keynote presentations. The summit was held February 13 to 15 in Myrtle Beach, South Carolina.

The Summit kicked off Tuesday afternoon with alliantgroup’s Tyler Noesser’s technical education workshop “Strategic Practices for Success” which focused strategies for employee retention, a hot topic in today’s competitive business landscape. Attendees packed the room, eager to gain insight into strategies for keeping valuable team members engaged and committed.

The highlight of the first evening was the Welcome Reception which commenced with the opening of the Exhibit Hall. Against the backdrop of 30+ exhibitors, attendees enjoyed drinks and appetizers while fostering professional connections and exploring new opportunities for collaboration.

The opening remarks on Wednesday saw Joe DeMan of Interconnect Dynamics—An Amephenol Global Solutions Provider, hand over the Board Chair title to Parker Garrett of EMSCO.

Garrett, a former member of the Navy himself, introduced the day’s first keynote “Turn the Ship Around!” presented by David Marquet, retired Navy Captain. Drawing from his experience as a Navy submarine captain, Marquet delivered powerful insights on leadership, emphasizing the importance of teamwork and trust. Notable quotes such as "Giving orders became the last resort, not the first resort" resonated with the audience, as Marquet urged leaders to empower their teams to make decisions and foster a culture of collaboration.

Later that day, speaker Cara Silletto of Magnet Culture presented “The Case for Change: Critical Workforce Insights for Leaders” focused on building loyal workers and provided valuable perspectives on workforce dynamics by challenging traditional notions of loyalty and highlighting the importance of communication and understanding in today's evolving workplace.

The afternoon’s keynote was delivered by Brian Fretwell whose session “Building Cultures of Connection” delivered ideas on overcoming negativity bias and fostering a culture of appreciation and offered practical strategies for promoting positivity and recognition in the workplace.

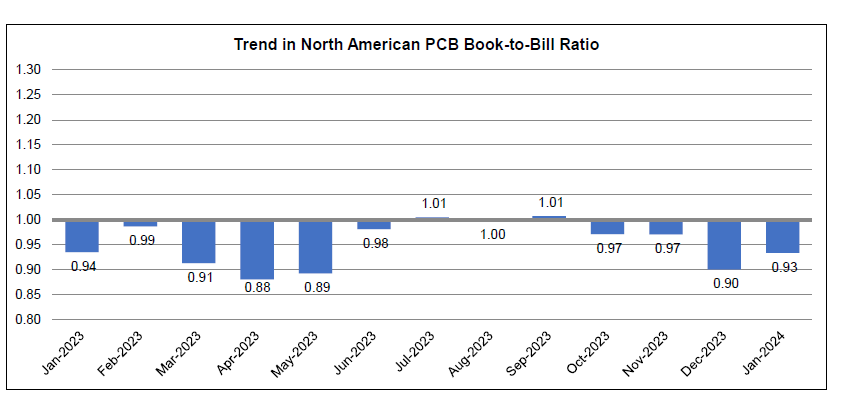

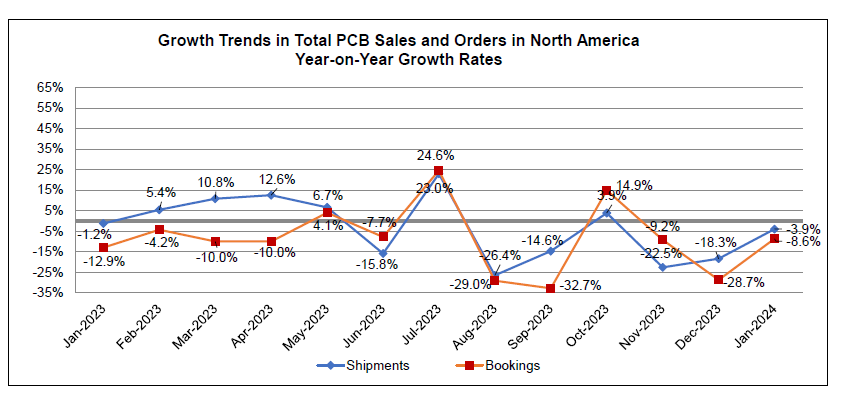

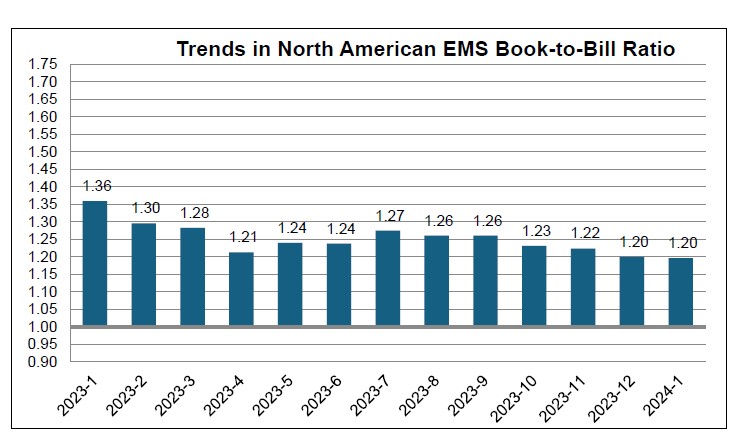

The last day of WHMA's Annual Global Leadership Summit started with IPC’s Chief Economist, Shawn DuBravac, and his insights into the future of the electronics industry presented in his keynote “From Now to Next: The Emerging Trends Reshaping the Electronics Industry.” After Dubravac’s prescient presentation it was all fun and games with author and speaker Steve Baker's keynote and workshop “Get in the Game: How to Create Rapid Financial Results and Lasting Cultural Change.” Attendees learned how to "gamify" the workplace to increase employee engagement.

Thursday’s keynotes were followed by Best Practice Roundtables where attendees were able to gain technical knowledge from industry experts. The summit ended with a Wine and Cheese Reception which gave attendees a final chance to network and chat with their peers in the industry.

Reflecting on the Summit, Program Committee Chair Doug Chowning of American Syscomptel stated, "The program committee selected speakers that could provide tools that attendees could implement quickly to help their businesses. Attendees of WHMA’s Global Leadership Summit agreed that this goal was achieved.”

Among the attendees, George Jacob, CEO of E-TRON Systems, remarked how useful the Summit is from a business perspective. Jacob underscored the benefit of networking at WHMA’s Annual Global Leadership Summit, “When we speak with other executives of other companies in the industry at the Summit we find that we are all facing the same challenges and talk about possible solutions.”

Mitch Elbers, employee of Dakota Fluid Power emphasized the significance of networking in addressing common industry challenges such as employee retention and supply chain issues, “At the Summit, we are able to bounce ideas off of other companies who are in the industry. We find solutions just by talking to each other and sharing our experiences.”

Overall, WHMA's Annual Global Leadership Summit proved to be a dynamic platform for knowledge sharing, networking and collaboration, leaving attendees inspired and equipped with valuable insights to drive success in their respective industries.

To view photos from 2024 Annual Global Leadership Summit, click here.