Excel Electronics, Inc. Earns IPC J-STD-001 and IPC-A-610 Qualified Manufacturers Listing Recertification

Under IPC's Validation Services Program, Excel Electronics Inc. has earned an IPC J-STD-001 and IPC-A-610 Qualified Manufacturers Listing (QML) Class 2 recertification. The company continues to be a trusted source and supplier, meeting the stringent requirements of the QML based on two of IPC's foremost standards: IPC J-STD-001, Requirements for Soldered Electrical and Electronic Assemblies and IPC-A-610, Acceptability of Electronic Assemblies.

Chip Estep, president of Excel Electronics Inc. stated, “Excel Electronics is proud to once again have earned the distinguished IPC Qualified Manufacturing Listing. The in-depth audit validated that the people and processes we have in place comply with IPC standards which are accepted as best practices throughout the world.” Estep added, “Randy Cherry, IPC’s Validation Services Program auditor is clearly a partner and valuable asset to Excel Electronics as we strive for continuous improvement to the quality of our products while reducing the cost to produce these products.”

IPC's Validations Services QPL/QML Program was developed to promote supply chain verification. It also provides auditing and certification of electronics companies' products and identifies processes that conform to IPC standards.

"Different from other audit programs, IPC's Validation Services Program uniquely provides technical and in-depth assessments of products and processes in accordance with IPC standards," said Randy Cherry, IPC director of Validation Services. "We are pleased to recognize Excel Electronics Inc. for achieving recertification to the J-STD-001/IPC-A-610 QML Program and continuing as a member of IPC’s network of trusted QML suppliers."

For more information about IPC's Validation Services QPL/QML Program, visit www.ipcvalidation.org or contact Randy Cherry at RandyCherry@ipc.org or +1 847-597-2806.

At IPC’s Urging, European Commission Takes Closer Look at EMS, PCB Sectors

By Alison James, Senior Director, IPC Europe

Today, the European Commission put a spotlight on the EMS and PCB industries with the goal of better understanding the region’s strategic dependencies in electronics manufacturing and implications for the broader manufacturing sector. The Commission’s Directorate General for Internal Market, Industry, Entrepreneurship and SMEs (DG GROW) called the meeting of key industry stakeholders, which included leading companies from the renewable energy, aerospace/defense, automotive, and industrial sectors.

The DG GROW dialogue was called on the heels of an IPC meeting in April that brought together government leaders and the key segments of the electronics industry to press for an EU strategy to strengthen silicon-to-systems innovation and manufacturing. This April IPC meeting highlighted a stark reality: key EU priorities—including those for semiconductor leadership, digitalization, and circularity—are contingent upon a robust European electronics manufacturing sector that has faced significant erosion over the last two decades. The electronics industry, though largely hidden from consumers, is an enabler of innovation and resiliency across all sectors of the economy.

Key officials at DG GROW attended the IPC April meeting. DG GROW was responsive to the concerns of industry and the need to understand better the electronics supply chain, to define existing and future risks to EU strategic autonomy and identify potential policy interventions. To this end, DG GROW organized today’s structured dialogue within one of its principal mechanisms for external expert engagement – the Industrial Forum.

IPC’s Senior Director for Solutions Dr. Hans-Peter Tranitz began today’s meeting by providing participants with a presentation on the electronics manufacturing supply chain and the importance of a strong silicon-to-systems ecosystem. Later, in my role as head of IPC government relations in Brussels, I made the case for the industry’s policy priorities, which include the EU:

- Affirming clearly the strategic importance of PCB and EMS manufacturing

- Funding R&D initiatives to ensure that PCB and EMS capabilities exist in Europe to complement advancements in chip fabrication.

- Supporting investments in capital equipment to bolster European manufacturing capabilities and facilitate the industry’s migration to the factory of the future.

- Strengthening the workforce pipeline and creating career pathways with industry-recognized training programs.

- Resolving disparate trade treatment that discourages domestic sourcing of electronics.

IPC was joined in its call for regional action by executives ACB (France), AT&S (Austria), InCap (Finland), and Zollner (Germany).

IPC appreciates that DG GROW has demonstrated its interest in these industrial challenges and has initiated near-term goals to further define with the industry the market challenges and policy needs. IPC, together with our members and partners, will continue to work with the European Commission on these issues in the coming weeks and months.

North American PCB Industry Sales Up 6.7 Percent in May

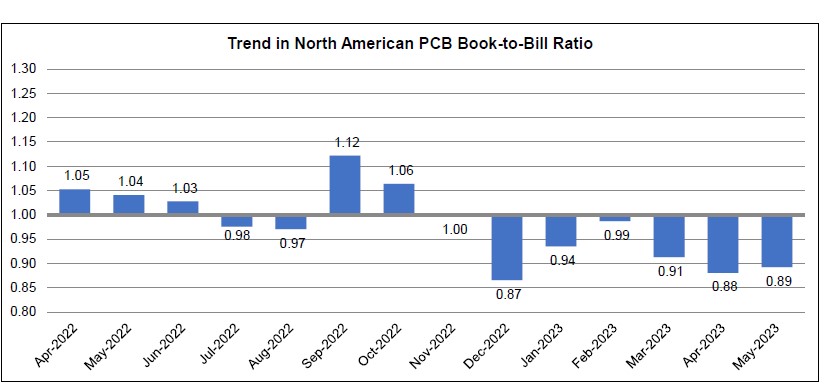

IPC announced today the May 2023 findings from its North American Printed Circuit Board (PCB) Statistical Program. The book-to-bill ratio stands at 0.89.

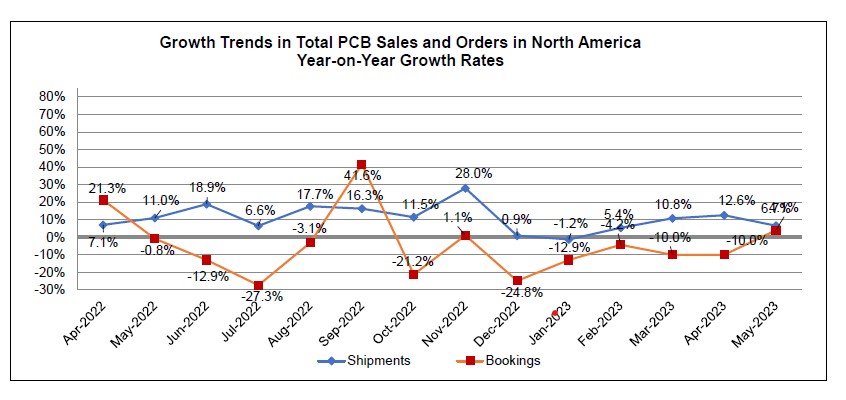

Total North American PCB shipments in May 2023 were up 6.7 percent compared to the same month last year. Compared to the preceding month, May shipments were down 1.9 percent.

PCB bookings in May were up 4.1 percent compared to the same month last year. May bookings were up 6.7 percent compared to the preceding month.

“The North American PCB market looks pretty balanced this month. Shipments remain strong and we saw the first year-over-year rise in bookings we've seen since November 2022,” said Shawn DuBravac, IPC’s chief economist.

Detailed Data Available

Companies that participate in IPC’s North American PCB Statistical Program have access to detailed findings on rigid PCB and flexible circuit sales and orders, including separate rigid and flex book-to-bill ratios, growth trends by product types and company size tiers, demand for prototypes, sales growth to military and medical markets, and other timely data.

Interpreting the Data

The book-to-bill ratios are calculated by dividing the value of orders booked over the past three months by the value of sales billed during the same period from companies in IPC’s survey sample. A ratio of more than 1.00 suggests that current demand is ahead of supply, which is a positive indicator for sales growth over the next three to twelve months. A ratio of less than 1.00 indicates the reverse.

Year-on-year and year-to-date growth rates provide the most meaningful view of industry growth. Month-to-month comparisons should be made with caution as they reflect seasonal effects and short-term volatility. Because bookings tend to be more volatile than shipments, changes in the book-to-bill ratios from month to month might not be significant unless a trend of more than three consecutive months is apparent. It is also important to consider changes in both bookings and shipments to understand what is driving changes in the book-to-bill ratio.

IPC’s monthly PCB industry statistics are based on data provided by a representative sample of both rigid PCB and flexible circuit manufacturers selling in the USA and Canada. IPC publishes the PCB book-to-bill ratio by the end of each month.

North American EMS Industry Up 7.1 Percent in May

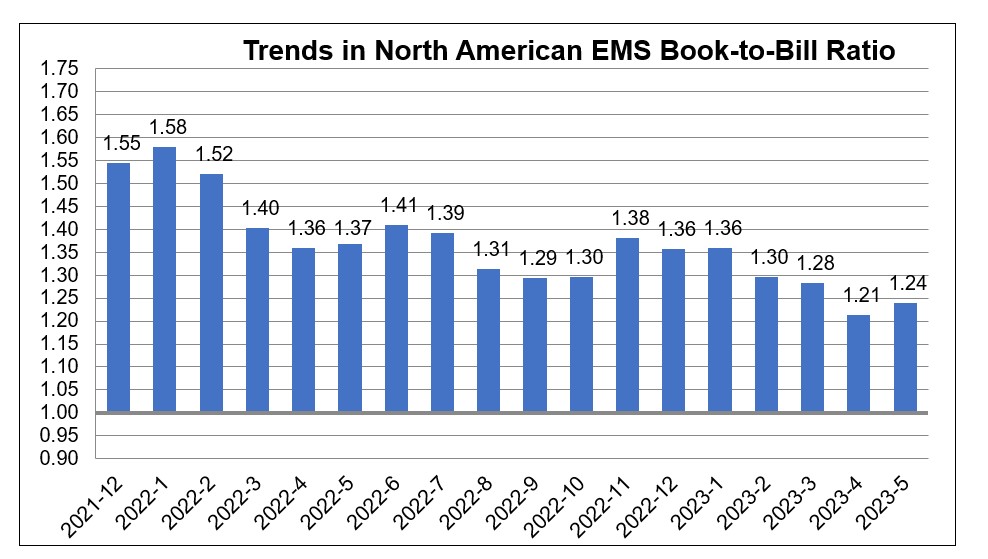

IPC announced today the May 2023 findings from its North American Electronics Manufacturing Services (EMS) Statistical Program. The book-to-bill ratio stands at 1.24.

Total North American EMS shipments in May 2023 were up 7.1 percent compared to the same month last year. Compared to the preceding month, May shipments decreased 5.2 percent.

EMS bookings in May increased 0.8 percent year-over-year and increased 4.4 percent from the previous month.

“This month we saw a small reversal in the trend we have been seeing this year,” said Shawn DuBravac, IPC’s chief economist. “New orders rose on a year-over-year basis for the first time since October 2022. Shipments fell slightly compared to last month but continue to show a positive trend.”

Detailed Data Available

Companies that participate in IPC’s North American EMS Statistical Program have access to detailed findings on EMS sales growth by type of production and company size tier, order growth and backlogs by company size tier, vertical market growth, the EMS book-to-bill ratio, 3-month and 12-month sales outlooks, and other timely data.

Interpreting the Data

The book-to-bill ratios are calculated by dividing the value of orders booked over the past three months by the value of sales billed during the same period from companies in IPC’s survey sample. A ratio of more than 1.00 suggests that current demand is ahead of supply, which is a positive indicator for sales growth over the next three to twelve months. A ratio of less than 1.00 indicates the reverse.

Year-on-year and year-to-date growth rates provide the most meaningful view of industry growth. Month-to-month comparisons should be made with caution as they reflect seasonal effects and short-term volatility. Because bookings tend to be more volatile than shipments, changes in the book-to-bill ratios from month to month might not be significant unless a trend of more than three consecutive months is apparent. It is also important to consider changes in both bookings and shipments to understand what is driving changes in the book-to-bill ratio.

IPC’s monthly EMS industry statistics are based on data provided by a representative sample of assembly equipment manufacturers selling in the USA and Canada. IPC publishes the EMS book-to-bill ratio by the end of each month.

IPC President and CEO Dr. John W. Mitchell Releases New Book, “Fire Your Hiring Habits”

Fire Your Hiring Habits: Building an Environment that Attracts Top Talent in Today's Workforce, by IPC President and CEO Dr. John W. Mitchell has been published by Forbes Books and is now available. Proceeds from the book will go to the IPC Education Foundation (IPCEF) to support careers in the electronics manufacturing industry.

In Fire Your Hiring Habits, Mitchell shakes up the hiring status quo with his views on the changing hiring landscape, and how businesses can attract and retain top talent today. Using real-world examples culled from Mitchell’s career, his book tackles relevant workforce issues such as recruiting and onboarding, talent pipelines, upskilling, corporate culture and more.

Within the book, Mitchell reframes The Great Resignation as a Great Reprioritization on the part of workers, and perhaps more importantly, a Great Reimagining for leaders, noting that employers are missing the key factors that motivate good people to stay, and the reasons why they leave in today’s business environment.

"How we structure our organizations, how we acquire talent, and how we interact with staff will determine the long-term viability of our companies,” explains Mitchell. “This book is all about helping leaders that are anxious about their long-term hiring prospects and embracing new ways of retaining talent.”

Fire Your Hiring Habits: Building an Environment that Attracts Top Talent in Today's Workforce is available on Amazon, Barnes & Noble, and Audible. To learn more about Mitchell’s book, visit https://johnwmitchell.com/book/.

IPC Launches Three Cutting-edge Online Instructor-led Courses to Empower Electronics Industry Professionals

IPC announces the launch of three new online courses designed to equip professionals with valuable knowledge and skills in the rapidly evolving electronics sector. Available on IPC’s online education platform, IPC EDGE, these new courses will provide industry experts and enthusiasts with opportunities for growth and development.

- Top Lead-Free Production Defects and Issues: Causes, Remedies, and Prevention: This course offers participants an in-depth exploration of the challenges and solutions related to lead-free production. Developed by Dr. Jennie Hwang, this course is ideal for manufacturers, engineers, and quality assurance personnel seeking to enhance their understanding of lead-free assembly processes, minimize defects, and optimize production efficiency. With a comprehensive curriculum and interactive learning modules, participants will gain the expertise required to overcome common challenges in lead-free production.

- HDI Enabling Technology: Advanced Packaging: This course is a necessity for professionals looking to deepen their knowledge of high-density interconnect (HDI) technology. Developed by Mike Carano, this course explores cutting-edge techniques and emerging trends in HDI, enabling them to leverage advanced packaging technologies effectively. This course is perfect for design engineers, manufacturing professionals, and technology enthusiasts seeking to stay ahead in the rapidly evolving electronics landscape.

- Introduction to PCB Design Engineering: Designed as an introductory course, "Introduction to PCB Design Engineering" equips individuals with the fundamental principles of printed circuit board (PCB) design. Fil Arzola instructs participants on industry-standard software and teaches best practices for designing efficient and reliable PCB layouts. Whether you are a novice designer or an experienced professional seeking to refresh your skills, this course will enhance your understanding of PCB design and empower you to create cutting-edge electronic devices.

Each of these courses is delivered by an industry expert providing participants with a flexible and interactive learning experience. "We are thrilled to unveil these three exceptional courses as part of IPC's commitment to fostering knowledge, innovation, and professional growth within the electronics industry," said Carlos Plaza, senior director of education development at IPC. "These courses have been meticulously designed to address the evolving needs of industry professionals, equipping them with the skills and expertise required to excel in their careers."

By enrolling in these courses, participants will have the opportunity to:

- Gain insights from industry experts and thought leaders.

- Master the latest techniques and technologies in the electronics industry.

- Boost their professional credentials and advance their careers.

- Network and collaborate with fellow professionals and experts in the field.

- Stay updated with the latest industry standards and best practices.

For more information about these courses or to enroll, visit https://education.ipc.org.

IPC to Host 2nd Annual Integrated Electronics Manufacturing & Interconnections (IEMI) Event

In 2022, IPC celebrated a decade of successful support to India’s electronics manufacturing industry and launched a series of activities including member networking events and skill challenge competitions throughout India, culminating in the inaugural Integrated Electronics Manufacturing & Interconnections (IEMI) event in New Delhi and Bengaluru last August. Based on the success of last year’s event, IPC will once again play host to IEMI events in Chennai on August 1 and in Pune on August 3.

The event will bring together designers, manufacturers, traders, suppliers, service providers and technical experts to explore new business partnerships, gain technical knowledge and source products and services. IPC India has partnered with several in-country chambers of commerce and trade associations to arrange international delegate visits from Singapore, Malaysia, Thailand, Sri Lanka, South Africa, Middle East and Israel.

Event highlights include a welcome address from State Ministers, keynote addresses from industry leaders and experts, panel discussions, a vendor development program, business-to-business meetings with country delegates, skills challenge competition, standards development meetings, an exhibition, an awards ceremony and networking lunch. IEMI Chennai will focus on the aerospace and defense market sector and IEMI Pune will focus on the EV automotive sector.

Exhibiting companies include: JBC, HTL, Ray-Q, Indium, Mectronics, Advance Tech, Prodigy, Japan Unix, Zeiss, Vinrox, Signum, Static Systems, Miracle, Sumitron/Hakko, Nanotech, Biometric Cables and more.

“We are expecting 1,000+ visitors from India and an additional 10 countries to this year’s event,” said John Mitchell, IPC president and CEO. “India is a dynamic market for the global manufacturing industry, and iEMI proves that. I am confident that IEMI 2023 will help attendees expand their business prospects and forge new strategic partnerships while there!”

“One of the major attractions of IEMI 2023 will be a Vendor Development Program/Sourcing Meet,” said Gaurab Majumdar, executive director of IPC India. “With the objective of promoting the growth and development of Indian SMEs by improving their market access, IPC is committed to working with Indian and global OEMs, to help them meet potential EMS and wire harness suppliers.”

For more information on Integrated Electronics Manufacturing & Interconnections (IEMI), visit www.ipc.org/ipc-india-iemi or contact Majumdar at GaurabMajumdar@ipc.org.