IPC returns to productronica with a brand-new program for you to celebrate and discover more about the electronics manufacturing industry.

Productronica presents the entire range of technologies and solutions for electronics production and provides in-depth insights into the latest trends in practice-oriented forums and live demonstrations.

IPC Forum will take place at booth #A4-502 where presentations will cover a wide range of industry topics every day of the trade show. The goal of the forum is to facilitate knowledge exchange and networking within our community of electronics manufacturing professionals in a live and interactive environment.

The topics include:

Technology Solutions

IPC works with the industry to develop strong global and regional manufacturing ecosystems and resilient supply chains. Advanced semiconductor packaging requires IC substrate fabrication and directly impacts future PCB technology and assembly processes. Keeping the supply chain from silicon-to-systems successful, IPC is the advocate for the industry bringing together a wide variety of technologies to remain healthy and strong.

Design

A new electronic product cannot be successful without a proper design creation process. This process requires close collaboration across the supply chain. The IPC Design Initiative aims to build a global forum where OEMs, PCB manufacturers, EMS, advanced packaging experts, and EDA software providers can collaborate, share and advance next-generation design approaches together.

Connected Factory Exchange (CFX)

IPC-CFX is an industry-developed open international standard forming the foundation/backbone of Factory of the Future applications. As a plug-and-play solution, it simplifies and standardizes machine-to-machine communication while also facilitating machine-to-business and business-to-machine applications.

Learn how you can implement IPC-CFX on your factory floor and begin to reap immediate benefits in advanced manufacturing and closed loop, data analytics, sustainability, quality improvement, and cost reductions.

Sustainability

Companies within electronics industry supply chains are under pressure to identify sustainability targets, achieve these targets, and fulfill regulatory reporting requirements. IPC’s Sustainability for Electronics Initiative is focused on supporting members as they incorporate industry tools — including standards, education, advocacy, and solutions — to achieve their sustainability objectives.

Wire Harness - WHMA

The Wiring Harness Manufacturer’s Association® (WHMA) was established in 1993 to serve the global cable and wire harness industry. WHMA is the ONLY trade association exclusively representing the cable and wire harness manufacturing industry including manufacturers, their suppliers, and customers. Now a council of IPC, WHMA provides our members technical support through standards and education, access to leading-edge technology, benchmarking, and the ability to network with the leaders in wire processing equipment, services, and manufacturing.

View IPC Forum presentation schedule here.

How to attend?

You will be granted free access to the trade show with a special voucher: prod2023_IPC_Europe

Click here to redeem your free ticket.

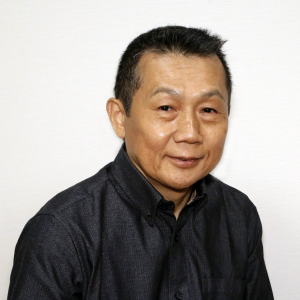

For more information, please contact Philippe Léonard, IPC Europe director (PhilippeLeonard@ipc.org)