Study on Manufacturing Process Standards applicable for Consumer Electronics & Mobile Industry

Background :

The Indian consumer electronics market is expected to be valued at $124.94 billion by 2030, witnessing a CAGR of 6.5% between 2023 and 2030. Competition & demand for affordable gadgets has led manufacturers to present innovative, durable, and cost-effective solutions to the market. It is important for manufacturers to invest in research and development in the manufacturing process & entire supply chain. Reliability & quality in the manufacturing process will remain one of the key factors to stay ahead of the curve.

Project :

India Cellular and Electronics Association (ICEA) has teamed up with IPC to study, find & improvise “Standards” applicable for design & manufacturing process in the assembly of printed circuit boards used in building consumer electronics devices, gadgets & appliances.

Primary Goal :

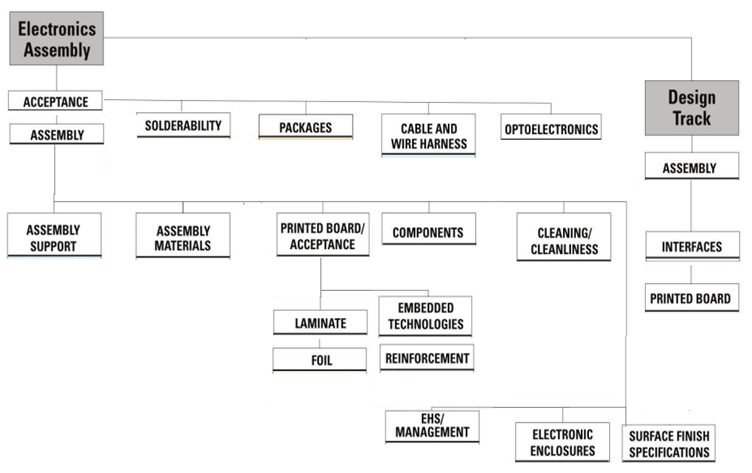

Develop or improvise process standards in the entire value chain from design, assembly, acceptability, inspection and testing of Printed Circuit Boards and interconnections leading to enclosures. PCB, components, assembly & interconnections become the most significant part of all types of electronic devices.

Value chain:

Secondary Goal:

Revision of skill development curriculum and training program for professionals & technicians involved with the electronics industry manufacturing & supply.

About IPC :

www.ipc.org: The Global not for profit Trade Association established in 1957 in the USA representing all facets of the electronics industry as members from 75 countries including India. IPC through its global offices, supports international cooperation and programs to meet the needs of an estimated $2.0 trillion global electronics industry. IPC members comprise OEMs, EMS, PCB manufacturers, cable and wire harness manufacturers, advanced packaging companies, and Electronics industry suppliers. Since 2010, IPC has regional presence in India and is responsible for supporting member companies to achieve high-quality end product in the manufacturing process through standards, certification and skill training.

Roadmap :

A) Investigating the Process/Standards Gap Analysis: Development of relevant questionnaires for survey on the quality issues challenging the entire manufacturing process, addressed to the departments:

• Quality & Production

• Research, Design & Development

• Repair & rework

Target Companies:

• Mobile Manufacturing

• LED television & laptop Manufacturing

• Telecom equipment

B) Examine & identify the problems – root cause/findings:

• Identify one or two companies, sign NDA and examine the issue(s) on-site, studying current processes and gathering feedback from employees and customers

C) Develop Task Group

• Invite industry members, Government, subject matter experts

• Form a Task Group/Committee

• Work on Recommendations & develop industry best practices and standards

D) Develop content/curriculum for training/skill development

E) Organize the industry Train the Trainer program