AGENDA

AGENDA

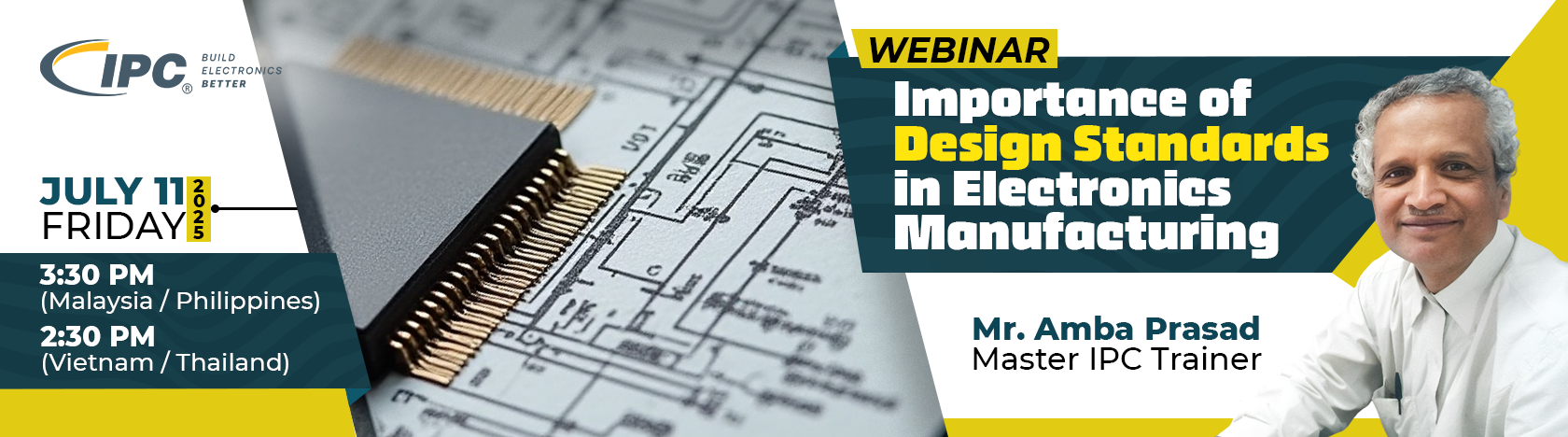

3:30 PM | Welcome Address by IPC – Dr. Ranee Ramya, Country Manager, Malaysia |

3:35 PM | Presentation on “Importance of Design Standards in Electronic Manufacturing” by Mr. Amba Prasad, Master IPC Trainer |

4:15 PM | Q & A Session |

Industry importance

Industry importance

Design standards play a critical role in the electronics manufacturing process. Errors found during final testing often trace back to the early design phase - whether it's PCB layout, component selection, or placement. In fact, up to 70% of product failures in electronics are traced back to design flaws, Implementing standardized design practices can reduce manufacturing defects by 20-40%, helping control the entire process, reducing the chances of failure, and ensuring product reliability. Good design not only supports functionality but also ensures that products can be manufactured efficiently and meet quality expectations. Design standards also improve first-pass yield by up to 35%, meaning more products are made right the first time, reducing costly rework.

One of the most widely recognized guidelines sets in this field is the “Design Standards” developed by IPC. By following them, teams across the development chain can work more efficiently, reduce errors, and produce reliable and consistent products that meet industry and customer expectations. These standards act as a common language between designers, engineers, and manufacturers, which improves coordination and reduces miscommunication. Following IPC standards helps keep the process steady and ensures every product functions properly from the very beginning.

Objective

Objective

This session aims to create awareness about the various IPC electronics design standards developed for assembly, interfaces, and the printed board industry. These standards help members maintain consistent parameters for PCB quality assurance and reliability, enabling them to meet customer expectations while improving production processes in multiple ways. IPC standards ensure that members produce safe, reliable, and high-performing PCBs that uphold industry excellence.

While not taught in today’s traditional education system, designers can obtain the necessary knowledge and skills to enhance their capabilities by following IPC design standards and completing Certified Interconnect Designer programs. This is especially important as most layouts have critical intricacies and it is important to implement or verify correctly.

Who can participate?

Who can participate?

Professionals involved in electronics manufacturing and assembly, including PCB designers, process engineers, quality assurance specialists, and product development teams seeking to enhance their knowledge of industry design standards and improve manufacturing outcomes.

About Speaker

About Speaker

Mr. Amba Prasad has been Product Architect at Tejas Networks and IPC Volunteer Instructor since 2015. He has disciplinary hands-on role in product development activities for carrier class communication equipment, including PCB and backplane layouts. This includes materials and processes for pcb, backplanes, and power supply modules, starting from schematic definition, constraints management, physical layouts, and fabrication of proto-PCBs, DFA resolutions for assemblies. Has defined DFM, DFA and Constraints Management Flows involved in High-Speed System Design Requirements. Additionally, he conducts IPC Designer Course for IPC Members.